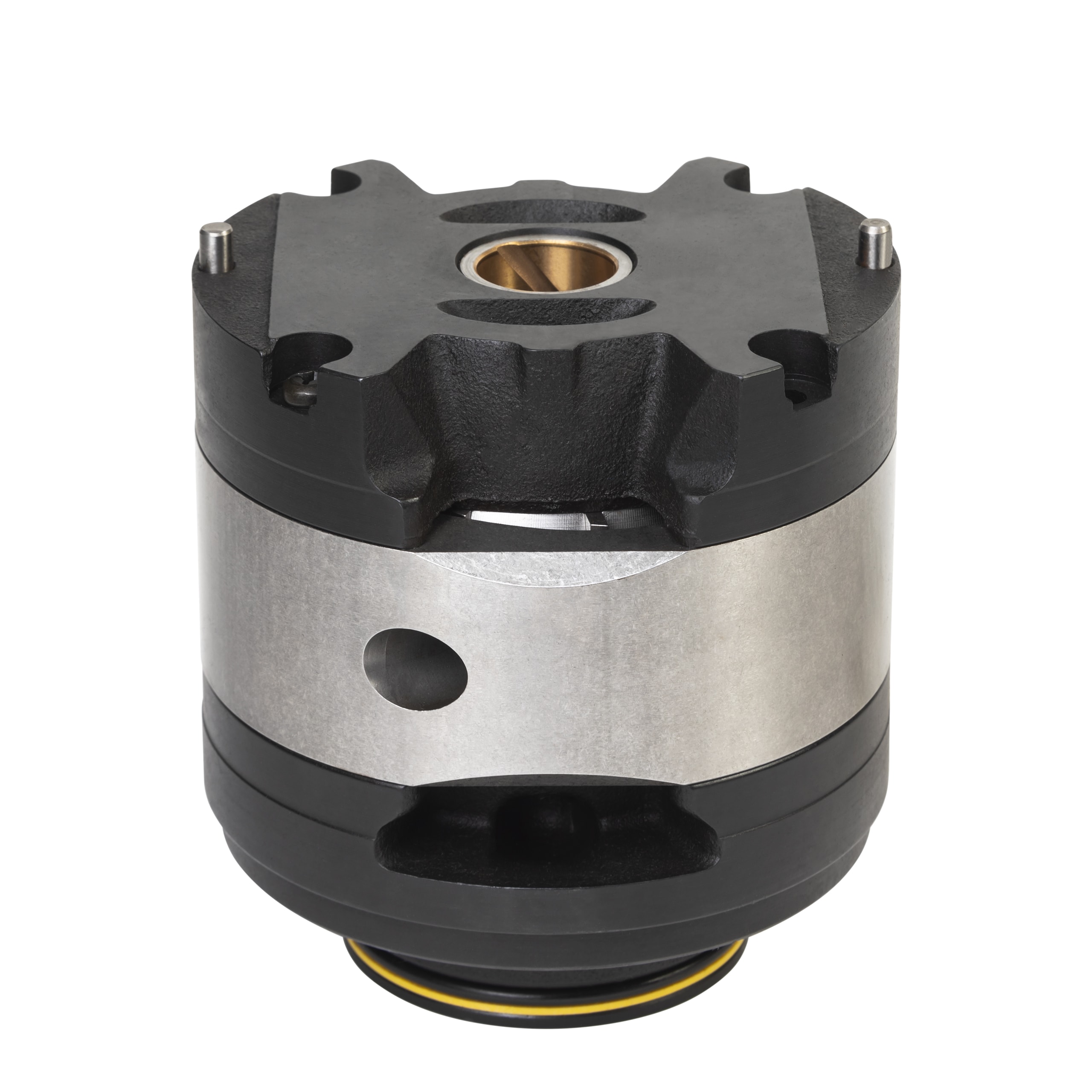

There are varieties of displacement selections for this vane pump cartridge from 32,0 to 79,2 ml/rev. The max pressure can support up to 210 bar for the instance use case. Also, The rotation speed supports from 600 to 2700 r/min using the different oil types.This vane pump allows low flow at high pressure and high flow at lower pressure. A clever way to optimize your circuit design and to sustain consistency power and flow. This pump also provides fast pressure cycle change with a precise flow.

Here are links for Single Pump kit:

Here are several links for Single, Double and Triple Pumps use this kit for replacement:

VQ Series Double and Triple Pump Cartridge Rear Kit 3525-VQ 4525-VQ 3525-VQSV10 4525-VQSV10

VQ Series Double and Triple Pump Cartridge Front Kit 2520VQ 2520VQSV10

Vane Pump Cartridge More Features & Benefits:

- Reduced energy consumption: Up to 90% Efficiency; reduces heat generation.

- Low noise level: Optimized for the lowest noise level in the smallest envelope.

- Increased lifetime: Double lip vane design raises dirt resistance to increase lifetime.

- Easy installation: Use the same body for all displacements. The port orientation allows customized installation.

Applications:

- Presses

- Agricultural

- Construction

- Material handling

- Lubrication

- Machines tools

General Applications Instructions:

- Check speed range, pressure, temperature, fluid quality, fluid viscosity, and pump rotation.

- Check the inlet conditions of the pump, if it can accept the application requirements.

- Check the type of shaft: if it will support the operating torque.

- Check the coupling to cut pump shaft load (weight, misalignment).

- Filtration: must be adequate for the lowest contamination level.

- Check the environment of the pump: avoid noise reflection, pollution, and shocks.

Start-up :

- Fill the tank up with a clean fluid in proper conditions.

- We recommend flushing the system with an external pump before the start-up.

- It is important to bleed the air off the circuit & the pump itself.

- The first valve on the circuit should be open to the tank.

- We recommend the use of air bleed-off valves.It is possible to bleed off the air by creating a leak in the P port of the pump.

More:

- We stock replacement parts for our VQ and V series aftermarket line.

- We are expanding our product range, so please check back often for our new product offering.

- If you have special requests, feel free to contact us. By the way, we have a strong project team for customized requirements.

Reviews

There are no reviews yet.